Fibre Splicing Explained: A Guide to Seamless Optical Connectivity

What is Fibre Splicing?

Fibre splicing refers to the process of joining two optical fibres end-to-end to create a continuous optical path. The goal is to minimise optical loss and back reflection while maintaining the fibre’s mechanical strength. Splicing is commonly used during fibre optic network installations, maintenance and repairs.

There are two main types of fibre splicing:

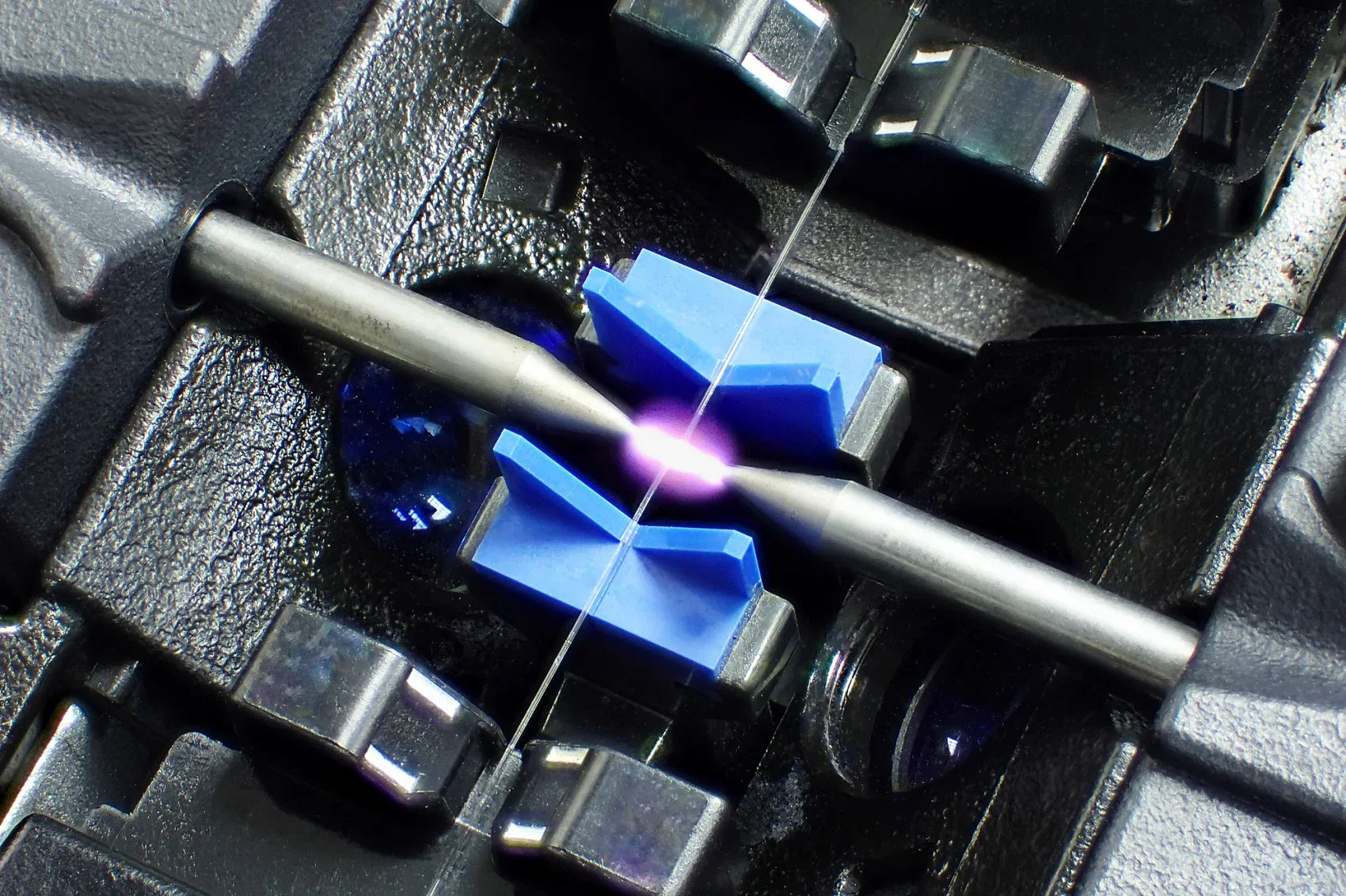

- Fusion splicing – the most common and precise method. This involves melting the ends of two fibres together using an electric arc.

- Mechanical splicing – involves aligning the fibres inside a small mechanical sleeve, often with index-matching gel to reduce losses. While quicker, it’s less durable and not typically used in high-performance applications.

At TT Instruments, we work exclusively with fusion splicers due to their superior optical performance and reliability.

How Does a Fusion Splicer Work?

A fusion splicer is a precision tool designed to automate the splicing process. Here’s a step-by-step overview of how it works:

- Stripping: The fibre’s protective coating is removed using a stripping tool to expose the bare glass core.

- Cleaning: The bare fibre is cleaned with alcohol to remove any dust or oils.

- Cleaving: Each fibre is cleaved (cut) using a special cleaver to produce a perfectly flat end-face.

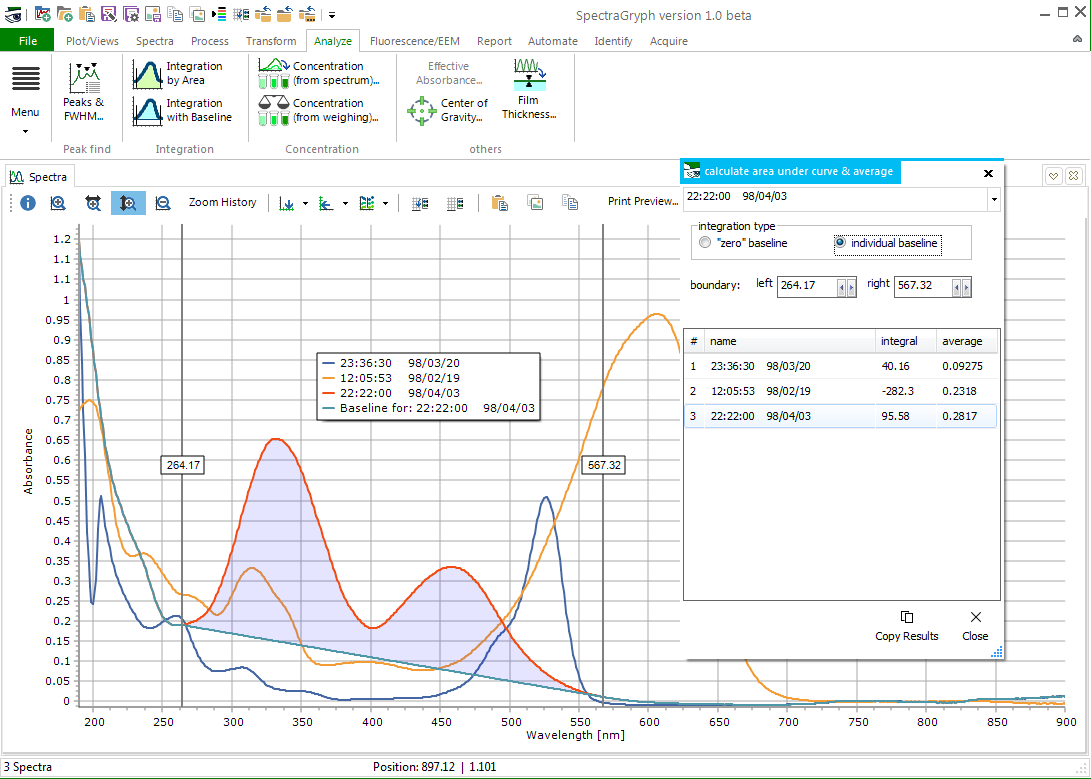

- Alignment: The splicer uses high-resolution cameras and motors to automatically align the fibre ends to within microns.

- Fusion: An electric arc melts the glass ends, fusing them into a single, continuous fibre.

- Inspection: The splicer analyses the splice and estimates the optical loss (typically <0.1 dB).

- Protection: A splice sleeve is applied over the joint and heat-shrunk to protect it from mechanical damage.

This entire process typically takes under 2 minutes.

Applications of Fibre Splicers

Fusion splicing is used in:

- Telecommunications networks

- FTTH (Fibre To The Home) installations

- Data centres

- Military and aerospace fibre systems

- Medical and industrial sensing networks

Splicers are vital whenever fibre cables must be extended, repaired, or re-routed. With networks increasingly relying on fibre, splicers are becoming standard tools across multiple industries.

Key Manufacturers

The most trusted names in the field are Fujikura and Sumitomo, both of which offer high-performance splicers suitable for everything from field installations to precision lab use.

If you’re looking to explore available units, you can browse TT Instruments’ Fibre Optic Test Equipment collection.

Useful Learning Resources

- How to Perform Fusion Splicing – VIAVI Video

- Understanding Fibre Splicing – Fibre Optic Association (FOA)

- Sumitomo Splicing Training Guides

Final Thoughts

Fusion splicers are the unsung heroes of fibre optic networks. While most people think of fast internet as simply a service, the technology enabling it relies on the precise work done by splicers in the field. Whether you’re working in telecoms, data centres, or fibre research, understanding how splicers work – and choosing the right one – is essential.

At TT Instruments, we offer a rotating selection of professionally tested, high-quality fibre splicers, perfect for engineers, technicians, and research labs.

Browse our Fiber Optic collection or get in touch for help finding the right equipment for your needs.